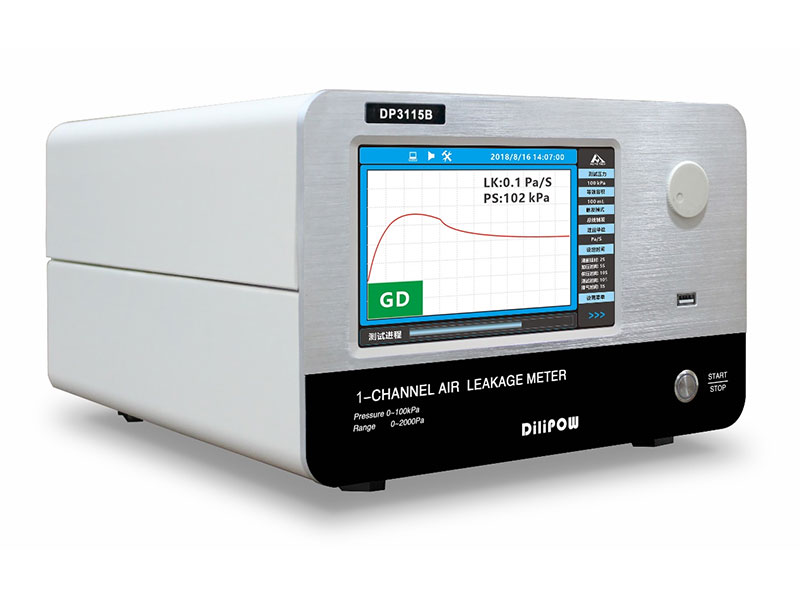

DP3115B series is an air tightness tester developed for the new energy vehicle industry. It adopts multi-channel differential pressure design, which is less affected by external factors, high test accuracy and good long-term stability. It uses color touch screen display, supports setting parameters and test data saving, test pressure programmable setting, and equipped with PC and PLC interface.

DP3115B is a differential pressure air tightness tester used to check the air tightness of various components and finished products, which can improve the leak detection ability and realize the automation of the inspection station. This instrument is equipped with a high-sensitivity differential pressure sensor and a pneumatic valve that is not affected by heat, and the operation of the pneumatic valve and the sensitivity of the sensor are automatically checked in each test. The basic circuit is composed of a self-test function with excellent function and safety, and the test capability and test time are shortened by using the standard error correction and setting function, or the error reduction function. It is fit for a wide range of test products and can accurately display the test pressure, differential pressure, and leakage amount.

- Test pressure programmable

- 5.4 inch touch screen, Chinese/English operation interface

- The waveform graph is displayed to facilitate the analysis of the inspection process

- The differential pressure resolution is 0.1Pa, and high accuracy

- Multi-channel parameterization and storage

- 8 channels of IO control signals, convenient for PLC docking

- Single-channel and 4-channel testing options for efficient multi-station testing

- It has a manual test mode and an automatic test mode

- External interface RS232/LAN

- 10,000 sets of test data can be saved, and test results can be queried by date

- It has rich data statistics and analysis functions

- It has the function of power-off memory protection

- Standard test pressure 10~100 kPa (negative pressure optional)

| Model | DP3115B | DP3115B-4 | |

| Test channel no. | single channel | 4-channel | |

| Differential pressure test | Minimum display | standard: 0.1Pa | |

| sensor range | standard: ±2000 Pa | ||

| Sensor pressure | standard: ± 2000 Pa | ||

| Display accuracy | ±5%rdg.±0.05%f.s. | ||

| Direct pressure test | Minimum display | standard: 0.1kPa | |

| Sensor setting | standard:0-100 kPa | ||

| Test pressure | 10k-100kPa | ||

| Display accuracy | ±5%rdg.±2% f.s. | ||

| Leakage rate setting | Leakage rate unit setting | Pa/min Pa/s | |

| The upper limit of leakage | 0~999.9Pa/mine | ||

| Time | Setting range | 0~999.9s | |

| Resolution | 0.1s | ||

| Power supply | AC100~240V ± 10%; Frequency: 50/60Hz | ||

| Pressure source | using a high flow, high pressure, and clean air pressure source. Connect the stable air adjusted by the pressure regulating valve | ||

| Pilot pressure | using clean air regulated to a pressure range of 400~700kPa | ||

| Pipe connection diameter | (test pressure source, test sample pipe, standard sample pipe) 6mm nylon pipe (drive pressure) 8mm quick plug joint (connect drive pressure source with 8mm outer diameter nylon pipe) | ||

| Control I/O interface | open collector specification interface and relay output | ||

| Communication | RS232 | ||

| Environmental temperature and humidity | usage temperature of 5-40 ° C, storage temperature -20~70C; below 80% RH, but without condensation | ||

| USB | Using USB to copy measurement data | ||

| Host size | 417mm(L)*281mm(w)*197mm(H) | ||

| Standard assembly (back) | air filter for driving pressure | ||